The Invisible Bottlenecks: How to See and Conquer the Hidden Challenges in Your Warehouse

- Sebastien Bouthillette

- Mar 14, 2025

- 3 min read

Updated: Jun 10, 2025

The warehouse. A dynamic hub of activity, the heart of your supply chain, where goods flow in and out, orders are fulfilled, and efficiency reigns supreme... or does it? The truth is, many Aussie warehouses are quietly battling invisible bottlenecks, hidden inefficiencies that subtly put the brakes on productivity and can cost a bomb in lost revenue. These challenges, often overlooked in the daily hustle and bustle of operations, can impact businesses of all sizes, from bustling city distribution centers to sprawling regional warehouses.

And these challenges aren't just limited to the warehouse floor. Many Aussie businesses find themselves caught in a frustrating WMS dilemma. They can settle for the basic functionality of WMS modules integrated within their ERP platforms – convenient, sure, but often about as useful as a screen door on a submarine when it comes to managing the complexities of a modern warehouse. These systems, with their clunky, list-based interfaces inherited from the ERP, can overwhelm floor staff with irrelevant information, hindering efficient operations and making it harder to get the job done right.

For those seeking more advanced capabilities, Tier 1 ERP suites like SAP, Microsoft Dynamics, or Oracle Business Suite beckon with their powerful features. Yet, this power comes at a premium cost, and often fails to address the fundamental issue of user experience. Even with robust functionalities, these systems often retain list-driven and overloaded interfaces, creating a disconnect between the system's potential and the practical needs of the warehouse workforce.

Then there's the option of standalone WMS solutions, promising specialized features and optimization tools. But these often carry prohibitive price tags, placing them out of reach for smaller and medium-sized operators. More affordable "Inventory Management Systems," while potentially offering better usability, frequently lack the crucial advanced functionalities required for truly efficient warehouse management. This leaves a significant gap in the market, where businesses struggle to find a solution that balances power, usability, and affordability.

But the challenges don't stop there. Take, for instance, the persistent reliance on paper-based processes. In this digital age, it's a bit baffling that many warehouses still grapple with paper trails for tasks like picking, put-away, and inventory tracking. This seemingly innocuous practice can really put a spanner in the works, leading to errors, delays, and a lack of real-time visibility – all of which chip away at your hard-earned efficiency.

Then there's the issue of static storage strategies. Many warehouses assign fixed locations for specific items, regardless of demand fluctuations. This results in underutilized space, increased travel distances, and a lack of agility in responding to the ever-changing demands of the Aussie market. These inefficiencies, though not always glaringly obvious, contribute to higher costs and slower fulfillment, impacting your bottom line.

Traditional warehouse training often relies on on-the-job learning, which can be a bit like chucking someone in the deep end. This time-consuming approach is prone to errors and safety hazards, with new employees potentially struggling to grasp the intricacies of warehouse layout and workflows. Meanwhile, data, though often plentiful, can be like a jigsaw puzzle with missing pieces – fragmented and difficult to interpret. Warehouse managers struggle to get a good overview of their operations, making it tricky to identify and address those pesky bottlenecks effectively.

These invisible bottlenecks, from clunky ERP systems to paper-based processes, collectively hinder a warehouse's true potential. They put the brakes on efficiency, stifle growth, and prevent businesses from achieving operational excellence.

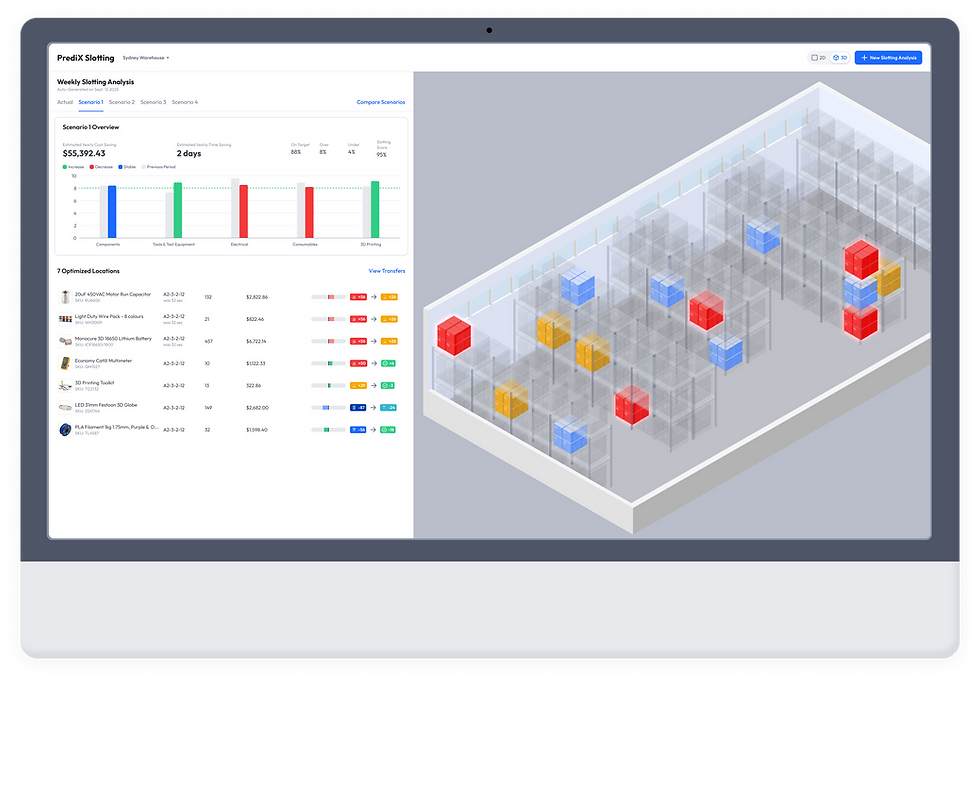

But what if there was a way to shine a light on these bottlenecks, to bring them into focus and tackle them head-on? What if you could visualize your warehouse in its entirety, a dynamic, interactive 3D representation that allows you to manage operations in real-time, just like a footy coach analyzing a game?

This is the power of 3DLogistiX. We're not just offering a new WMS; we're introducing a paradigm shift in warehouse management, designed specifically with the challenges of the Aussie market in mind.

Intuitive control: Navigate your warehouse with ease, using an interface as user-friendly as your favourite app.

Advanced functionality, accessible to all: Optimize picking routes, manage inventory in real-time, and gain actionable insights, all within an intuitive and affordable platform that won't break the bank.

Visualize your warehouse: See your inventory, track your equipment, and manage your workflows with unprecedented clarity, no matter how spread out your operation is.

3DLogistiX is about empowering your workforce, optimizing your operations, and unlocking the true potential of your warehouse. It's about conquering the invisible bottlenecks and achieving a new level of efficiency and productivity, all while keeping things fair dinkum.

Don't get left behind – join the 3DLogistiX revolution today! Be one of the first to experience the future of warehouse management – contact us now for a free demo.