Picking and Packing Optimisation for Small Warehouses Strategies

- Sebastien Bouthillette

- May 2, 2025

- 3 min read

Updated: Jun 10, 2025

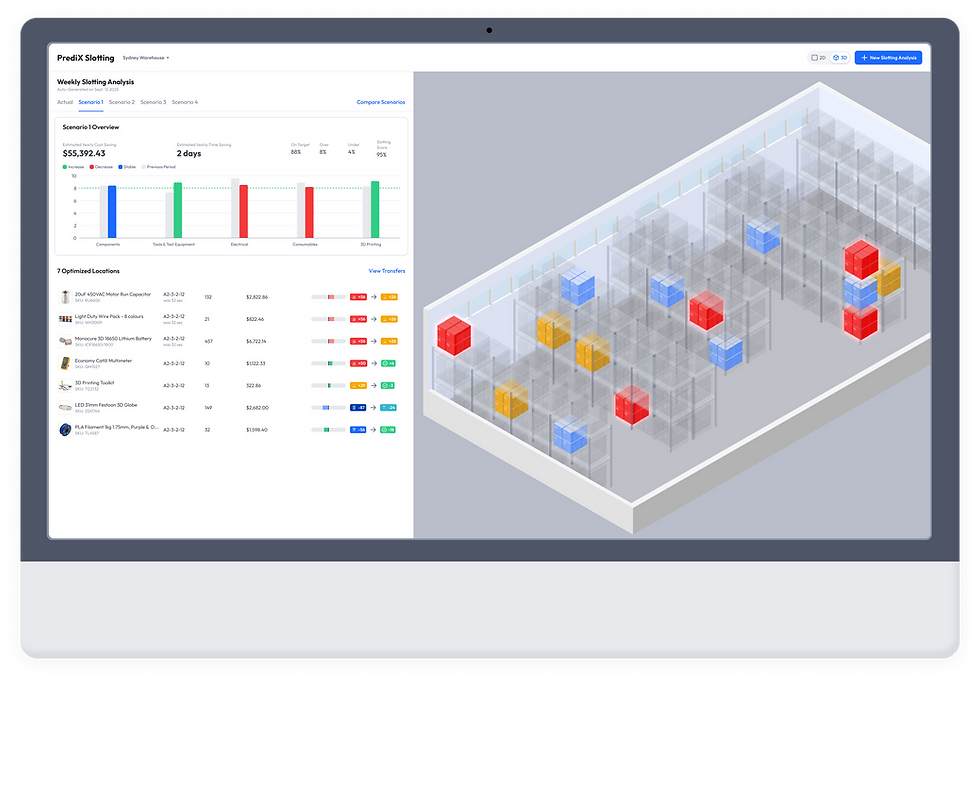

For SMEs in Australia and New Zealand, efficient picking and packing are crucial for timely order fulfilment and customer satisfaction. Traditional picking and packing methods often involve manual processes, leading to errors, delays, and increased labour costs. 3DLogistiX warehouse management system offers advanced 3D visualisation and optimisation tools to streamline picking and packing, enabling SMEs to achieve precision and speed in their warehouse operations.

This post explores how 3DLogistiX optimises picking and packing for SMEs, improving accuracy, reducing costs, and enhancing the customer experience.

The Importance of Efficient Picking and Packing in Small Warehouses

Picking and packing are critical steps in the order fulfilment process, directly affecting order accuracy. Inefficient picking and packing logistics, including poor warehouse layout, can lead to:

Order Errors: Incorrect items or quantities shipped, resulting in returns and customer dissatisfaction.

Delays in Shipping: Slow picking and packing processes lead to longer order processing times.

Increased Labour Costs: Manual picking and packing require significant labour resources.

Damage to Goods: Inefficient packing can result in damage to products during shipping.

Inefficient Use of Warehouse Space: Poor picking and packing processes can lead to inefficient use of warehouse space.

3DLogistiX addresses these challenges by providing tools and visual aids that streamline the picking and packing process, improving efficiency and accuracy in order fulfillment.

Picking and Packing Optimisation for Small Warehouses Key Features

3DLogistiX offers several key features that optimise picking and packing by employing effective picking strategies:

Guided Picking: 3D visualisation provides pickers with the most efficient routes based on the warehouse layout, minimising travel time and reducing errors.

Visual Packing Instructions: 3DLogistiX can provide visual instructions for optimal packing, reducing damage to goods and minimising shipping costs.

Integration with Barcode Scanners: Streamlines the picking and packing process, improving accuracy and speed.

Real-time Inventory Updates: 3DLogistiX automatically updates inventory levels as items are picked and packed, ensuring accurate stock records.

Order Verification: 3DLogistiX can verify orders before they are shipped, minimising errors and improving customer satisfaction.

Research by the Warehousing Education and Research Council (WERC) highlights that optimised picking and packing processes can reduce order fulfilment costs by up to 35% (WERC, 2022). 3DLogistiX's optimisation tools empower SMEs to achieve these cost savings and improve their order fulfillment efficiency.

Picking and Packing Optimisation for Small Businesses Practical Application

3DLogistiX's picking and packing optimisation features can be applied to various tasks, including:

Order Fulfilment: Streamlined and accurate picking and packing for faster order processing and delivery.

Inventory Management: Real-time inventory updates and order verification for improved stock control.

Warehouse Efficiency: Optimised picking routes and packing processes for efficient use of warehouse space and resources.

Customer Satisfaction: Reduced order errors and faster shipping for enhanced customer experience.

Your Warehouse is Only as Fast as the System That Runs It

3DLogistiX optimises picking and packing for SMEs through its advanced 3D visualisation and optimisation tools. By streamlining these crucial processes, 3DLogistiX enables SMEs to achieve precision and speed in their order fulfilment, reduce costs, and enhance customer satisfaction.

Ready to optimise your picking and packing processes and improve your order fulfilment efficiency? Schedule a personalised demo of 3DLogistiX today and discover how our innovative solutions can enhance your business efficiency.