Warehouse Management Trends in 2025: AI, Robotics, and 3D Digital Twins

- Sebastien Bouthillette

- May 15, 2025

- 5 min read

Updated: Jun 10, 2025

In the fast-paced world of logistics, the warehouse is no longer a simple storage space, it is the brain of the supply chain. In 2025, warehouse management trends are evolving rapidly, driven by new technologies like AI, robotics, and 3D digital twin warehouses.

For businesses looking to stay competitive, understanding and adopting innovations in the supply chain are no longer an option; they are essential.

In this article, I dive into the biggest shifts shaping the future of warehousing.

1. AI in Warehouse Management: Smarter, Faster Decisions

Artificial intelligence (AI) is no longer just a buzzword. In warehouse management, AI is being used to transform operations in real-time, significantly boosting productivity and accuracy. AI-powered systems analyse vast amounts of data to optimise inventory levels, predict demand fluctuations, and automate routine decision-making. Machine learning algorithms can identify patterns and inefficiencies that would be difficult for humans to detect, enabling continuous improvement across all warehouse processes. As AI becomes more deeply integrated, warehouses are able to respond swiftly to market changes, minimise errors, and deliver superior service to customers.

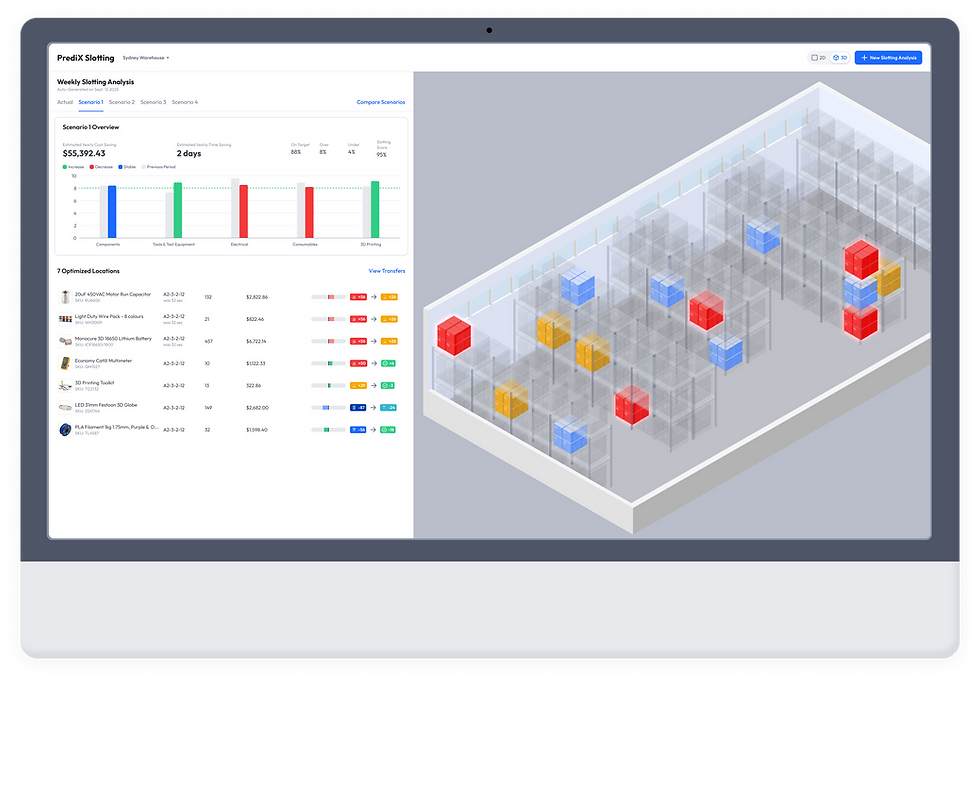

Dynamic Slotting and Inventory Optimisation: AI analyses SKU velocity, seasonality, and picking patterns to optimise storage locations dynamically, improving picking speeds and reducing congestion.

Autonomous Task Assignment: Staff no longer need to manually receive tasks. AI-powered systems autonomously assign tasks based on location, workload, and priority, dramatically increasing warehouse efficiency.

Predictive Maintenance: AI models forecast equipment failures before they happen, reducing downtime and extending the life of critical warehouse machinery.

Real-Time Analytics: AI interprets real-time data from sensors and warehouse management systems (WMS) to recommend immediate actions that improve throughput and reduce bottlenecks.

Why it matters: Warehouses leveraging AI in warehouse management can achieve 20–40% faster pick rates, 15–25% lower inventory holding costs, and significantly improve customer satisfaction.

2. Warehouse Robotics: Automation That Works Alongside People

Warehouse robotics continues to redefine the relationship between human workers and machines, particularly in streamlining order fulfilment processes. Advanced robots now collaborate with employees, handling repetitive or physically demanding tasks while allowing humans to focus on more complex problem-solving and quality control. This synergy not only increases overall productivity but also improves workplace safety and job satisfaction. As robotics technology evolves, warehouses benefit from faster picking, packing, and shipping, ensuring that customer expectations for speed and accuracy are consistently met.

Autonomous Mobile Robots (AMRs): These robots navigate dynamic environments without predefined paths, assisting with picking, replenishment, and transportation tasks inside the warehouse.

Collaborative Robots (Cobots): Rather than replacing workers, cobots work with them — lifting heavy loads, preparing picks, and reducing physical strain on employees.

Automated Sorting and Packing: Robotic arms are now sophisticated enough to handle complex packing tasks, reducing error rates and improving shipping speed.

Why it matters: With labour shortages remaining a challenge, warehouse automation helps companies maintain productivity and output without overburdening staff, creating safer, more scalable operations.

3. 3D Digital Twin Warehouses: Total Visibility in Real Time

One of the most revolutionary smart warehouse technologies emerging in 2025 is the 3D warehouse digital twin, enhancing the accuracy of operations. By creating a real-time, virtual replica of the entire warehouse environment, digital twins allow managers to visualise workflows, monitor equipment, and identify inefficiencies before they impact productivity. The use of digital twins in supply chain and warehouse environments is projected to increase by more than 40% over the next two years.

This technology enables predictive maintenance, optimises space utilisation, and supports rapid scenario planning for unexpected disruptions. As a result, warehouses can achieve greater agility, reduce downtime, and make data-driven decisions with unprecedented precision.

Live 3D Mapping: Every pallet, forklift, and picker is represented digitally, updated in real-time. Managers can see exactly what’s happening in their facility from any device.

Simulated Planning: Want to test a new warehouse layout or slotting strategy for enhanced warehouse layout optimisation? You can simulate it virtually before making costly physical changes.

Immediate Bottleneck Detection: By analysing real-time movements and tasks with high accuracy, AI highlights inefficiencies like congested aisles or idle resources instantly.

Enhanced Safety: By monitoring both human and machine movements in 3D, safety risks are identified and mitigated before incidents occur.

Why it matters: A 3D digital twin warehouse can cut operational costs by up to 20% through improved resource planning and faster decision-making, ultimately boosting customer satisfaction.

4. Integration of Smart Warehouse Technology

No warehouse technology works in isolation. Smart warehouses integrate a wide array of advanced systems, including AI-driven analytics, robotics, and IoT-enabled sensors, to create seamless and highly efficient operations. These interconnected technologies enable real-time data sharing, predictive maintenance, and automated decision-making, resulting in faster order fulfilment and reduced operational costs. By leveraging this holistic approach, warehouses can quickly adapt to changing market demands and maintain a competitive edge in an increasingly dynamic supply chain landscape.

WMS platforms

Inventory management systems

IoT sensors

AI task management

Robotic fleets - into a seamless, data-driven ecosystem.

Warehouse managers will need solutions that offer real-time API integrations with platforms like Xero, MYOB, QuickBooks, and Shopify, predictive analytics dashboards, and automated task orchestration across systems.

Why it matters: An integrated smart warehouse provides unmatched responsiveness, from adjusting to late deliveries to rerouting picking during peak periods.

5. Sustainability-Driven Automation

Another rising warehouse management trend is green warehousing, which utilises trend analysis to enhance sustainability in the industry. AI and automation technologies help warehouses reduce energy consumption, minimise waste, and optimise resource allocation. By monitoring real-time data, these systems can identify opportunities to lower carbon emissions and implement eco-friendly practices, such as intelligent lighting and climate control. Additionally, automated inventory management reduces overstocking and spoilage, further supporting environmental goals. As sustainability becomes a core focus, green warehousing not only benefits the planet but also improves operational efficiency and brand reputation.

Reduce energy use by optimising lighting and HVAC systems dynamically.

Optimise delivery routing to cut fuel consumption.

Improve inventory rotation to minimise product waste.

Warehouses that embrace sustainability are not just reducing costs, they are strengthening their brand and future-proofing against new environmental regulations.

Key Takeaways: The Future of Warehousing Is Here

Exploding in 2025, leading warehouses will achieve new levels of efficiency and productivity through warehouse automation and will be recognised as pioneers in the logistics sector. These facilities will leverage advanced robotics, AI-driven systems, and real-time data analytics to optimise every aspect of their operations. Automated processes will streamline inventory management, order fulfilment, and shipping, allowing warehouses to handle unprecedented order volumes with remarkable speed and precision. This transformation will not only reduce operational costs and errors but also empower businesses to exceed customer expectations and adapt swiftly to market changes, solidifying their competitive advantage.

Powered by AI and machine learning for faster, smarter decisions

Staffed with humans and robots working side-by-side

Visualised with 3D digital twins for total operational transparency

Integrated through smart systems for maximum operational efficiency

Focused on sustainability as a competitive advantage

If you are not already exploring these warehouse management trends, including inventory control, now is the time.

See in Action these Warehouse Management Trends That Make You Ship Faster

Book a free demo with 3DlogistiX today and experience how AI-driven slotting, autonomous task assignment, real-time 3D visualisation, and layout optimisation can transform your operations.