SME Inventory Accuracy is Improved by 3D Visualisation

- Sebastien Bouthillette

- Jun 17, 2025

- 6 min read

For SMEs in Australia and New Zealand, accurate supply chain and inventory tracking is critical to operational success. Traditional inventory systems often rely on reactive reporting and manual checks, which can lead to inventory inaccuracies, inefficiencies, and gaps in supply chain performance. A modern warehouse management software and automated inventory system can bridge these gaps by offering enhanced digital inventory audits and real-time inventory control.

An effective inventory management system is vital for the coordination and execution of supply chain tasks. By centralising inventory data and processes within a comprehensive inventory control system, such a system reduces the chances of error and streamlines operations. This ensures real-time tracking of inventory within your digital warehouse environment, helping businesses maintain optimal stock levels and meet customer demands efficiently while empowering proactive inventory management strategies.

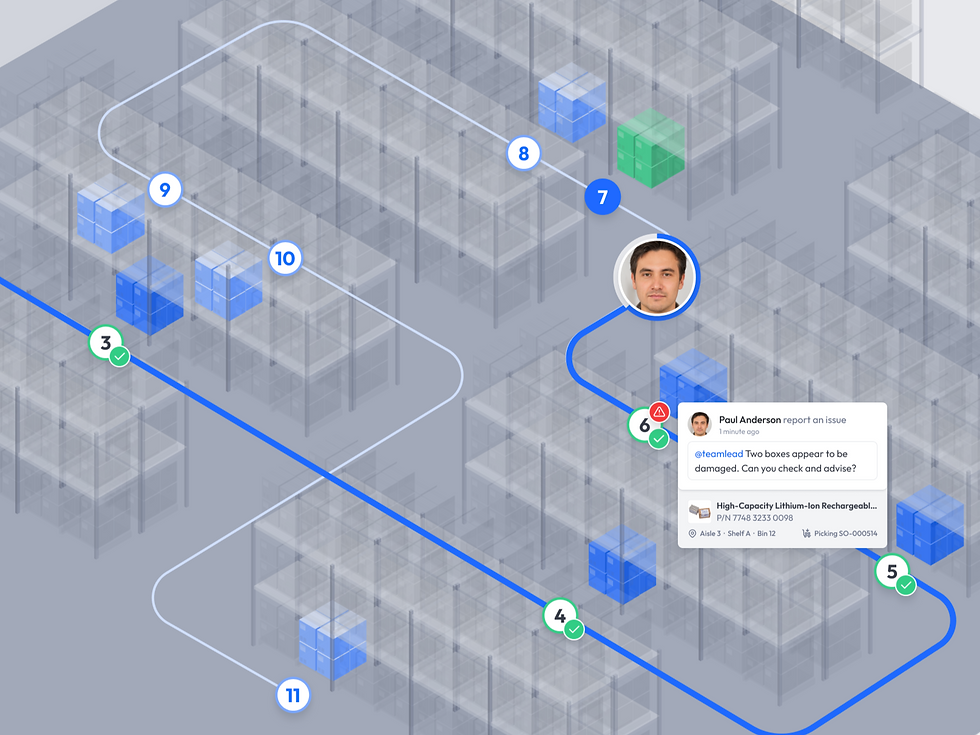

Enter 3DLogistiX: a next-generation warehouse management solution that blends 3D visualisation with intelligent automation tools like DynamiX Count and RepleniX. Together, they offer SMEs a powerful way to manage inventory with greater precision, speed, and confidence. This state-of-the-art inventory tracking system integrates digital supply chain solutions with AI-powered inventory slotting and automated reordering protocols.

What is inventory accuracy?

“Inventory accuracy” describes how closely an organisation’s recorded inventory levels align with the actual physical stock present in its warehouse or storage facilities. High inventory accuracy means that the numbers in your system match what is actually on the shelves, reducing the risk of errors, discrepancies, and lost opportunities in your automated inventory system. This alignment is crucial for effective inventory management, as it ensures that smart decision-making is based on reliable, real-time data.

When inventory is accurate, the records precisely represent the true quantity of items physically available, supporting efficient operations, better customer service, and sound financial reporting. Advanced digital inventory audits and warehouse management software bring this level of precision to your day-to-day operations.

Why inventory accuracy matters

Inventory accuracy is essential for organisational success, providing several important benefits. When inventory records match actual stock levels, operations run smoothly and efficiently. This accuracy helps reduce costs, prevent stockouts or overstocking, and ensures reliable financial reporting. It also improves customer satisfaction by enabling prompt and accurate order fulfilment, while supporting smarter forecasting, AI-powered demand planning, and regulatory compliance.

Improved operational efficiency Accurate records streamline daily operations, reduce time spent on manual inventory checks, and minimise discrepancies, leading to lower costs and higher productivity. Advanced inventory management automation enhances these results further.

Better financial performance Precise inventory data helps optimise stock levels, reduce carrying costs, and prevent losses from overstocking or stockouts. It also ensures accurate financial reporting and compliance with tax obligations by integrating seamlessly with your digital inventory control system.

Higher customer satisfaction When inventory is accurate, orders are fulfilled promptly and correctly, enhancing customer trust and encouraging repeat business. This is bolstered by real-time inventory monitoring and automated replenishment.

Smarter forecasting and planning Reliable inventory data enables better demand forecasting and more informed purchasing and production decisions, especially when integrated with AI analytics and digital inventory audits.

Regulatory compliance and reduced losses. Accurate records support regulatory compliance and help identify issues like theft, spoilage, or misplacement, reducing waste and losses through a secure digital inventory management system.

The Power of 3D Visualisation + Smart Inventory Tools

3DLogistiX enhances inventory accuracy not just through data, but through real-time visual insight, integrated with RFID technology for precise tracking across your supply chain. By leveraging advanced 3D visualisation, teams can instantly identify discrepancies, optimise storage layouts, and streamline stocktaking processes with an integrated warehouse management software. This dynamic approach empowers decision-makers with a clear, interactive overview of both inventory and digital supply chain performance, reducing errors and improving operational efficiency. Ultimately, 3DLogistiX transforms inventory management from a static, manual task into a proactive, data-driven strategy with automated inventory system capabilities.

DynamiX Count: Dynamically schedules cycle counts based on product movement and risk, integrating cycle counting automation for enhanced inventory accuracy and effective inventory control.

RepleniX: Automates stock replenishment using thresholds and real-time demand signals, thus making warehouse replenishment more efficient and accurate within a digital inventory system.

When paired with cutting-edge 3D visualisation, these smart inventory tools become even more intuitive. Users can interact with digital representations of their warehouse, making it easier to locate items, monitor stock levels, and identify inefficiencies in real time. These are hallmarks of a robust inventory management automation solution. The immersive experience allows for quicker training and onboarding, as staff gain hands-on experience with the workflow and processes powered by AI-driven analytics. This seamless integration of technology not only simplifies complex tasks but also drives greater accuracy and confidence in inventory management.

View stock status in a live warehouse layout

Instantly identify discrepancies through digital inventory audits

Monitor replenishment actions visually, not just in traditional reports

This synergy between automation and visualisation gives warehouse teams better situational awareness, enhances productivity, and enables faster response times in today’s competitive digital inventory environment.

The smartest way to achieve inventory accuracy

DynamiX Count® uses intelligent targeting to focus cycle counting on high-risk inventory areas, moving beyond static schedules to an automated, digital inventory tracking system. With 3D visualisation, users can instantly identify which zones or racks require attention. This 3D-driven cycle counting system operates seamlessly in the background, detecting discrepancies before they escalate into costly problems. When something is amiss, you’re notified immediately. Real-time alerts highlight discrepancies as soon as they arise, allowing you to address issues before they impact your bottom line. No more late night audits. No interruptions to daily operations. Just smarter decisions, powered by accurate, real-time data.

RepleniX® automatically replenishes inventory as soon as thresholds are reached, ensuring real-time stock visibility within the digital inventory system. Within the 3D interface, users can monitor replenishment tasks in real time and verify that stock is moving exactly where it’s needed. RepleniX® leverages a live 3D model to instantly highlight low-stock items, so you always have a clear view of what’s running low, its exact location, and what requires restocking. Your team benefits from a dynamic, up-to-date stock map that reflects inventory movements as they happen. When it’s time to reorder, replenishment suggestions are instantly converted into purchase orders, eliminating the need for spreadsheets and reducing manual entry. RepleniX® ensures fast-moving items are always available and slow-movers are kept out of the way, lowering carrying costs without sacrificing fulfilment. It proactively flags stock risks, automates reordering, and streamlines restocking, enabling your team to work faster with fewer steps and no manual effort, all features of a smart, digital inventory management solution.

PrediX Slotting®, a core feature, eliminates the guesswork from your warehouse layout. Driven by AI, it analyses your order history and predicts future demand, strategically positioning your fastest-moving items for rapid fulfilment. No more unnecessary shuffling, wasted time, or searching for stock. Instead, your inventory is always in the right place, ready to be picked and shipped quickly and accurately. This intelligent system reduces travel time, boosts picking efficiency, and maximises available storage. It consolidates slow-moving items and places high-demand products exactly where they’re needed for fast, precise fulfilment. From the moment new stock arrives, PrediX Slotting® reviews historical data and forecasts future trends, continuously adjusting your layout to match current and upcoming demand. It adapts in real time, keeping your warehouse lean, organised, and optimised for speed. An essential component of a fully integrated digital inventory control system.

Together, these advanced tools move your warehouse from guesswork to proactive inventory control, enhancing customer satisfaction by ensuring inventory accuracy and timely fulfilment using intelligent digital inventory systems.

Real World Applications for SMEs

3DLogistiX brings clarity and speed to everyday inventory and supply chain processes:

Real-Time Stock Monitoring: Watch stock levels change live with a digital inventory audit system, spotting potential shortages before they become problems.

Smart Stock Placement: Use visual heatmaps and AI-driven analytics to improve slotting based on demand and product movement.

Automated Replenishment Oversight: Monitor active replenishment tasks visually through an integrated warehouse management system, reducing the need for manual checks.

Virtual Inventory Audits: Use live 3D data to audit stock without physical inventory counts, effectively reducing disruptions and streamlining operations.

Why It Works: Visual Insight + Automation

According to the Warehouse Education and Research Council (WERC)* reports top-performing warehouses aiming for very high percentages, often above 99% for inventory accuracy. 3DLogistiX takes it further by combining this visual clarity with automation, real-time inventory tracking, and digital supply chain integration. The result is:

Fewer stock-outs

More accurate inventory counts, leading to improved inventory accuracy and enhanced digital inventory control

Lower carrying costs and minimise shrinkage

Conclusion: Better Accuracy Starts with Better Visibility

3DLogistiX empowers SMEs with tools that combine intuitive 3D visualisation, accurate records, and smart SME inventory management automation. By using DynamiX Count and RepleniX within a live digital warehouse view, you eliminate blind spots, reduce errors, and make faster, smarter decisions, ultimately transforming your traditional inventory management system into a modern, AI-powered supply chain solution.

If your warehouse is still relying on manual checks or outdated inventory systems, it’s time to step into the future with advanced inventory management automation.

Book a demo of 3DLogistiX today and see how superior digital visibility powers accuracy for growing SMEs through smart warehouse management software and integrated inventory control systems.